MACHINES・TOOLS

Training

- You will learn the operation and rules for each piece of equipment in the lab.

- Those who have not used the equipment for a long period of time and have forgotten how to operate it are required to take a refresher course.

Use Machines

- Please make a reservation to use the equipment in the lab.

- A fee will be charged for the use of the equipment.

- Consumables and materials for each piece of equipment to be used must be purchased by the user.

- Some equipment requires the presence of a staff member.

Advance preparation

- Please prepare data in advance before using the machines.

- Please consult us in advance regarding requests for making data, etc.

- Prepare and check materials.

- Note that some materials cannot be used depending on the machines

Introduction of machines and tools at FabLab West harima below.

1.CNC Machining

1-1 ) Digico-MILL48 Version 5

- A large wood router for building furniture and housing

- Fab Lab West harima Completely Original Machine

-->more details

| machine spec | Description |

|---|---|

| Processable materials | Wood, Processable materials (Acrylic, Polycarbonate, PVC, etc), aluminum |

| Work area | About 1300 mm(w) x 2500 mm (L) x 150 mm (H) |

| Feed rate | 1-3000 mm/min |

| Spindle speed | max 18000 r/min |

2.CNC milling

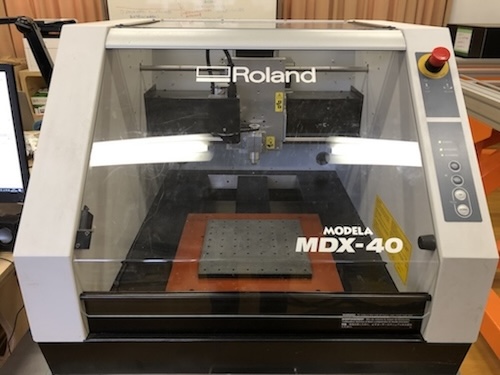

2-1) Roland_MODELA MDX-40A

- High-precision milling machine for cutting chemical wood (fake wood), resin, light metals, etc.

- Example: On-site rapid circuit prototyping

-

MDX-40 (Update to MDX-40A)

- Manual (Japanese)

| machine spec | Description |

|---|---|

| Cuttable material | Resins such as chemical wood and modeling wax (metal not sup- ported) |

| Work area | 305 (x) x 305 (y) x 105 (z) mm |

| Workpiece table size | Width x depth: 305 × 305 mm |

| Loadable workpiece weight | 4kg |

| Operating speed | XY axis: 7 to 3000 mm/min. Z axis: 7 to 1800 mm/min. |

| Spindle Motor | DC brushless motor, max 100W |

| Spindle rotation | 4,500 to 15,000 rpm |

| Overall Machine Size | 669 x 760 x 554 mm |

| Software resolution | 0.01mm/step (RML-1) 0.001mm/step (NC code) |

| Control command sets | RML-1, NC code |

| Computer | Model preinstalled with Windows 7, Vista (32/64-bit edition) or XP, or upgraded computer originally preinstalled with Windows XP or later |

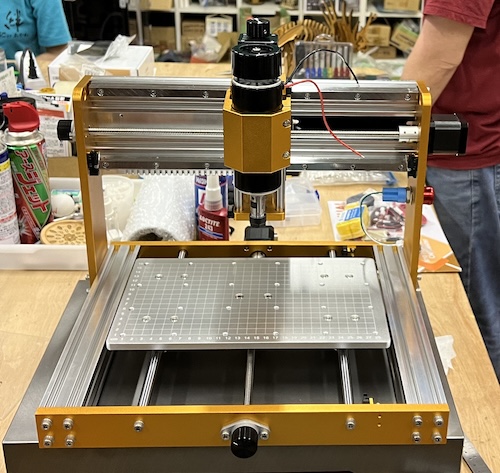

2-2) LUNYEE_3018 Pro Ultra

- High-precision milling machine for cutting chemical wood (fake wood), resin, light metals, etc.

- Example: On-site rapid circuit prototyping

| machine spec | Description |

|---|---|

| Cuttable material | Plastic, wood, aluminum, copper |

| Driver Chip | 3*A4988 |

| Control Board | 3 Axis 5.2 GRBL 1.1f |

| Machine Size | 485x415x374mm |

| Work area | 300x180x80mm |

| Precision | ±0.1 |

| Maximum operating speed | 5000mm/min |

| Maximum processing speed | 2000mm/min |

| Maximum acceleration | 200mm/s² |

| Spindle Power | 500W |

| Power | 48V 500W |

| Emergency stop switch | Support |

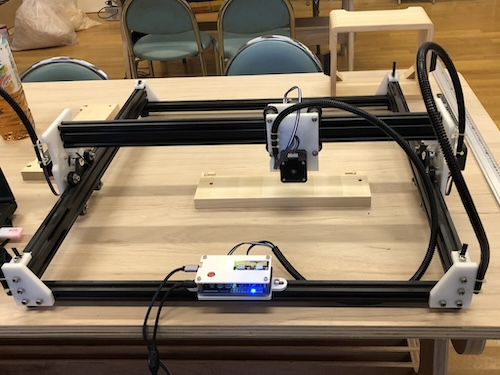

3. A laser cutter

- Cut and engrave paper, wood, acrylic and other board materials

3-1) LED Laser

- For engraving wood and other materials

3-2) FABOOL Laser CO2, 40W

- For engraving wood and acrylic, other materials

- Some materials such as chloride are not available.

4.Cutting Machine

4.1)silhouetter CAMEO 3

- Cutting sheets and paper cutting

- Sticker production, paper craft, substrate production (copper film), stencil plate production, etc.

| machine spec | Description |

|---|---|

| Attachable paper size | 304.8 mm (12inch) / 215.4mm (LETTER) / 210 mm (A4) |

| cut Speed | Max 100 mm/s |

| cut pressure | Max 2.1 N (210 gf) |

| Number of pens that can be attached | 2 |

| Cuttable materials | Film: Thickness 0.1 mm or less (excluding high-intensity reflective film) [Paper] Kent paper 157 g / m2, drawing paper, postcards, scrapbooking paper, inkjet photo paper, 0.5 mm thick paper |

| OS | Windows 10 / 8.1, Mac OS X 10.10 or higher |

5. 3D printer(3DP)

- Resin and other materials are output as three-dimensional objects based on 3D data.

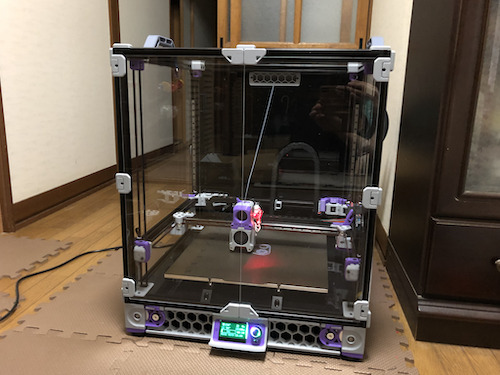

5-1) VORON 2

- Fused Deposition Modeling

- Hi Speed 3DP

- Open Source 3DP

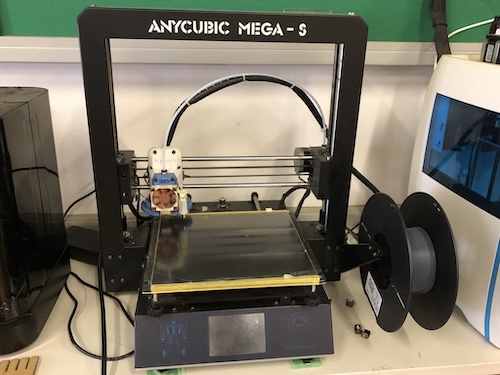

5-2) Anycubic Mega-3

- Fused Deposition Modeling

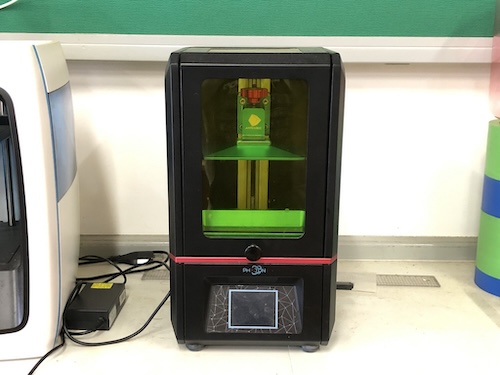

5-3) Any Cubic PHOTON

- LCD-based SLA (Stereolithography) technology

- Resin 3D printer

- Allergies Caution

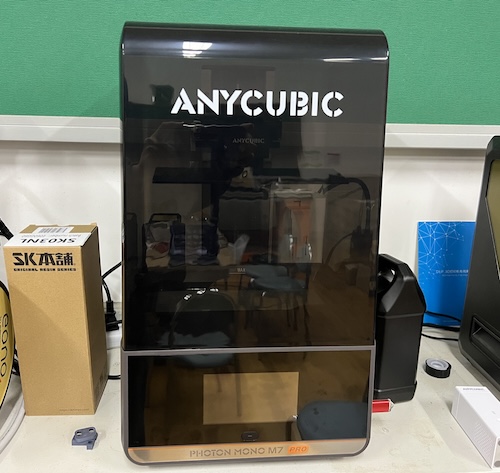

5-4) Anycubic_Photon Mono M7 Pro

- LCD-based SLA (Stereolithography) technology

- Resin 3D printer

- Allergies Caution

| machine spec | Description |

|---|---|

| light source | Light Turbo 3.0 (COB + Fresnel lens) |

| LCD screen | 10.1-inch Mono LCD |

| LCD resolution | 14K (13320 * 5120) |

| XY Resolution | 16.8*24.8μm |

| Printer dimensions | 315(L) 312(W) 520mm(H) |

| Work size | 126(D) 223(W) 230mm(H) |

| Software | Anycubic Slicing、CHITU、Tango |

| Printing Speed | Standard Resin:0.1mm layer height: 130mm/h peek speed |

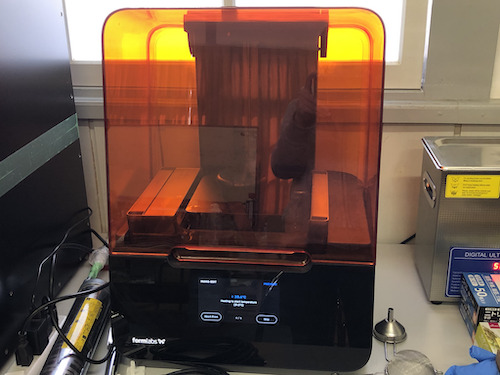

5-5) Form3

- LFS(Low Force Stereolithography)

- Industrial-quality resin 3D printer

- Allergies Caution

| machine spec | Description |

|---|---|

| Printing technology | SLA, LFS(Low Force Stereolithography) |

| Supported print materials | 30+ Functional Resins: |

| Layer pitch | 25- 300 micron |

| Support material | Automatic Generation |

| Work size | 145 x 145 x 185 mm |

| Printer dimensions | 405(W) x 375(D) x 530 (H) mm |

| Software | Preform |

| Official site | formlabs |

6.Tooles

6-1) mini-router

- PROXXON mini-router set MM100 No.28525-S

6-2) Airbrush

- AIRTEX Airbrush

Beauti4+ 0.3mm XP-B4B

6-3) Hand Tool

- Various tools